Benefits of Surface Finishing

Based on different surface finishing processes, your machined parts can achieve the following effects:

- Surface Roughness Control

- Enhance Wear Resistance

- Increased Corrosion Resistance

- Deburring & Sharpening

- Change Electrical Conductivity

- Reduce Surface Riction

- Increased Adhesion

- Texturing Pattern

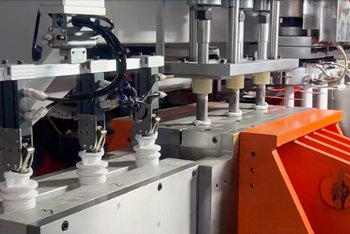

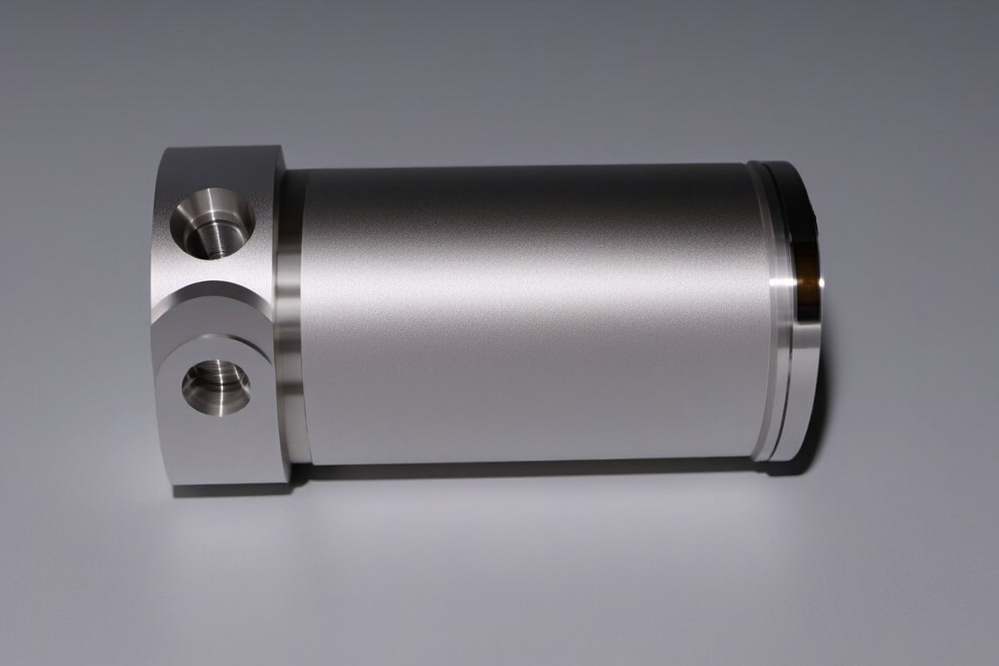

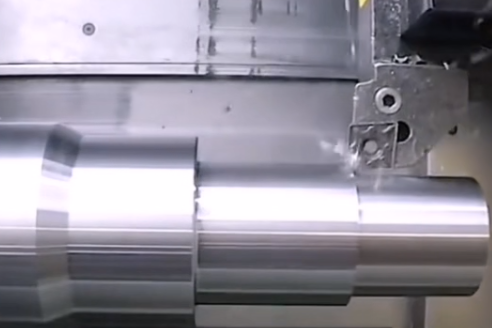

Our Surface Finishing Capabilities

Shangwei InnovateTech® provides numerous types of surface finishing options for your machined parts, ensuring a smooth surface that not only enhances the aesthetics but also improves functionality. The metal finish we offer is of the highest quality, guaranteeing durability and a long-lasting look. Additionally, our treatments are designed to enhance wear resistance, ensuring that your parts can withstand repeated use without showing signs of wear. Furthermore, we focus on increasing corrosion resistance, protecting your machined parts from the harmful effects of rust and corrosion, ensuring their longevity and performance over time.

Anodizing

Bead Blasting

Electroplating

Electroless Plating

Knurling

Laser Engraving

Metal Brushing

Metal Polishing

Powder Coating

Silk Printing

Spray Painting

Surface Grinding

Our Surface Finishing Specifications

There are a variety of surface finishing specifications. The following table shows the standards for common metal surface treatments.

| Category | Film Thickness (μm) | Color | Materials | Function |

|---|---|---|---|---|

| Aluminum Anodizing Black (B—HY) | 10-15μm | Black | Aluminum and its alloys | Decoration, Anti-oxidation |

| Aluminum Anodizing Red | 10-13μm | Red | Aluminum and its alloys | Decoration, Anti-oxidation |

| Aluminum Anodizing Blue | 10-13μm | Blue | Aluminum and its alloys | Decoration, Anti-oxidation |

| Aluminum Anodizing Green | 10-13μm | Green | Aluminum and its alloys | Decoration, Anti-oxidation |

| Natural Anodizing (B—BY) | 9-14μm | Bright | Aluminum and its alloys | Decoration, Anti-oxidation |

| Hard Natural Oxidation (B—YB) | 30-40μm | Bright Black | Aluminum and its alloys | Anti-oxidation, Anti-static, Improved wear resistance and hardness |

| Aluminum Hard Oxidation Black (B—YH) | 30-40μm | Black | Aluminum and its alloys | Anti-oxidation, Anti-static, Improved wear resistance and hardness |

| Aluminum Alloy Conductive Oxidation | 0.5-2μm | Silver White | Aluminum and its alloys | Stable contact resistance, Improved corrosion resistance |

| Natural Sandblasting Anodizing (B—BP) | 9-14μm | Bright Silver | Aluminum and its alloys | Decoration, Anti-oxidation |

| Black Sandblasting Anodizing (B—HP) | 10-15μm | Bright Black | Aluminum and its alloys | Decoration, Anti-oxidation |

| Hard Chrome Plating (B-DL) | 3-50μm | Blue White | Various metal steels | Anti-rust, Decoration, Increased wear resistance and hardness |

| Decorative Chromium Plating | 3-50um | Bright White | Various metal steels | Anti-rust, Decoration, Increased wear resistance and hardness |

| Powder Coating | 40—800μm (six grades) | Various metal steels and aluminum | Anti-rust, Decoration | |

| Spray Paint | 40-80μm | Baking Paint: Warm Gray C1 Matte | Various metal steels and aluminum | Anti-rust, Decoration |

| PTFE Non-stick Coating | 10-30μm | Black | Iron, Aluminum, Stainless Steel, etc. | Non-stick |

| Zirconium Oxide Ceramic Plating | 50-1000μm | Black | Aluminum and its alloys | High temperature resistance and hardness |

| Blackening | 1-2μm | Black, Deep Blue, Brown | Various metal steels | Anti-rust, Decoration |

| QPQ Salt Bath | 300-500μm (45# Steel) | Black | Various structural steels | Corrosion resistance, Fatigue resistance |

| Chromium Plating White | 0.5-2um | Silver White | Aluminum and its alloys | Stable contact resistance, Improved corrosion resistance |

| Stainless Steel Passivation | 0.3-0.6um | No change in appearance | Stainless Steel | Decoration, Anti-rust |

| Aluminum Alloy Chemical Bright White | 5-8um | Bright Silver White | Aluminum and its alloys | Decoration, Increased corrosion resistance |

| Galvanizing | 2-12μm | White, Blue, Colorful, Black | Various metal steels | Anti-rust, Decoration, Increased corrosion resistance |

| Titanium Plating | 3—4um | Various metal steels | Anti-rust, Decoration |

Why Choose Us?

Here are some bullet points explaining why customers should choose us for surface finishing services for CNC parts:

- Quality Assurance

- Advanced Technologies

- Competitive Pricing

- Experienced Team

- Timely Delivery

- Comprehensive Support

About Shangwei InnovateTech®

Shangwei InnovateTech has been in CNC machining industry for more than 20 years. Our technician are good at all kinds of surface finishing. By choosing us, you can be confident that your CNC parts will receive the highest quality surface treatment, delivered on time and within budget.